Project Description

Description

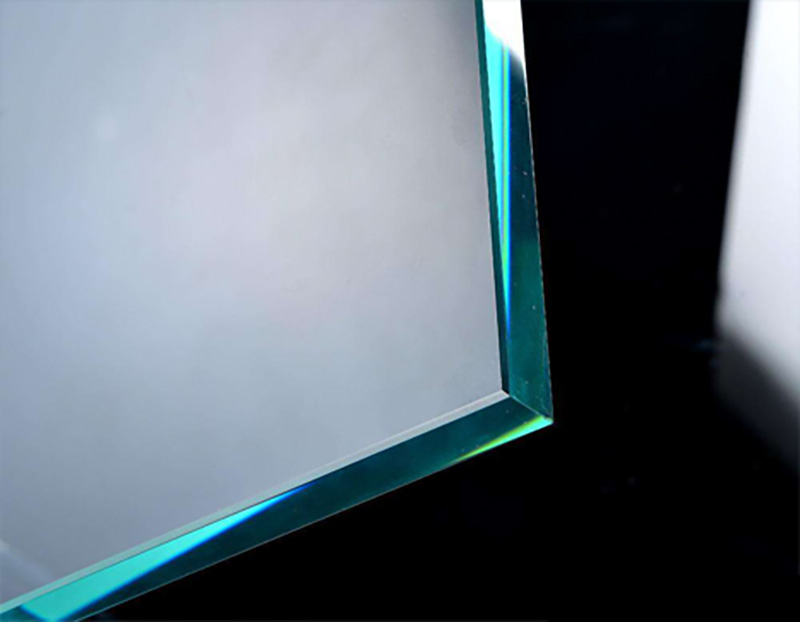

Tempered glass/Reinforced glass is a safety glass. Tempered glass is actually a type of prestressed glass. In order to increase the strength of the glass, a tempering furnace is usually used to form compressive stress on the surface of the glass. When the glass is subjected to external force, the surface stress is first offset, thereby improving the bearing capacity and enhancing the wind resistance of the glass itself. , cold and hot, shock and so on.

Advantages

- Safety: Small particles that break into a uniform obtuse and are not easy to injure when broken.

- Strength: The strength of tempered glass is 4-5 times that of ordinary glass.

- Thermal stability: can withstand 200 °C temperature difference changes

Techonlogy

Tempered glass is obtained by first cutting the ordinary annealed glass into the required size and then heating it to about 700 degrees near the softening point, and then performing rapid and uniform cooling (usually 5-6MM glass is heated at 700 °C for 240 seconds). Cool down for about 150 seconds. 8-10MM glass is heated at 700 °C for about 500 seconds, and the temperature is lowered by about 300 seconds. In short, depending on the thickness of the glass, the time for heating and cooling is different. After the tempering treatment, the surface of the glass forms a uniform compressive stress, while the inside forms a tensile stress, which improves the bending and impact strength of the glass, and its strength is about four times that of the ordinary annealed glass. Tempered tempered glass can not be processed or damaged by any cutting, grinding, etc.

Tempered Glass