Project Description

Description

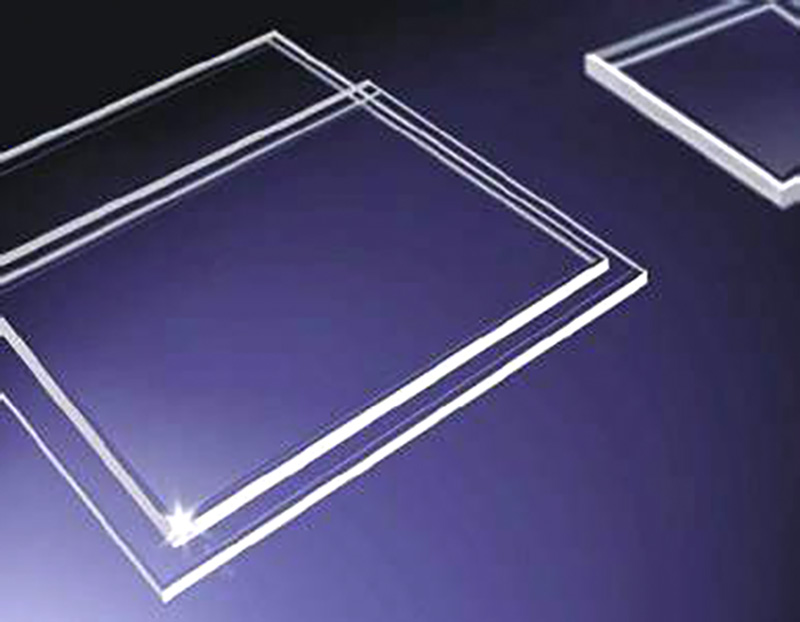

High borosilicate glass, also known as hard glass, is made by melting glass through heating in the interior of the glass under high temperature. It is also called “borosilicate glass 3.3” because of its linear thermal expansion coefficient (3.3 It is a kind of special glass material with low expansion rate, high temperature resistance, high strength, high hardness, high light transmittance and high chemical stability. Because of its excellent performance, it is widely used in solar energy, chemical industry, pharmaceutical packaging, electric light source, craft accessories and other industries. Its good performance has been widely recognized by all walks of life, especially in the field of solar energy more widely used, Germany, the United States and other developed countries have been more widely promoted.

Applications

High borosilicate glass has very low thermal expansion coefficient, high temperature resistance, 200 degree temperature difference drastic change.

SSM GLASS HIGH BOROSILICATE GLASS can be used extensively in applications such as;

Microwave oven panels, fireplace panels, halogen headlamps, and other high temperature contact surfaces.

Advantages

Borosilicate glass has very low thermal expansion coefficient, about 1/3 of ordinary glass. This will reduce the temperature gradient stress.

Therefore, it has stronger fracture resistance. Because of its very small shape deviation, it makes it a necessary material for telescope and reflector. It can also be used to treat highly radioactive nuclear waste.

The borosilicate glass began to soften at about 821 (1510), at which temperature the 7740 type viscous high borosilicate weights 107.6.

Borosilicate glass is denser than ordinary glass.

Although more and more borosilicate glasses are resistant to thermal shock than other types of glasses, they can still be broken by rapid or uneven temperature changes. When broken, borosilicate glass cracks tend to be larger, rather than crushed (it splits the elements, not splits).

Optically, borosilicate glass has low dispersion (about 65 Abbe number crown glasses) and relatively low refractive index (the entire visible range is 1.51-1.54).

The linear expansion coefficient of G3.3 high borosilicate glass is 3.3_0.1 65507 The content of boron and silicon in the glass is high, which are 12.5-13.5% and 78-80% respectively. Therefore, this kind of glass is called high borosilicate glass. It belongs to PYREX glass [1] in borosilicate glass. Acid and alkali resistance, water resistance, corrosion resistance superior, with good thermal stability, chemical stability and electrical properties, so with chemical corrosion resistance, thermal shock resistance, mechanical properties, high temperature and other

Techonlogy

Physical and chemical properties of G3.3 high borosilicate glass

| Silicon content | >80% |

| Strain temperature | 520℃ |

| Annealing temperature | 560℃ |

| Softening temperature | 820℃ |

| Refractive index | 1.47 |

| Transmittance (2 mm) | 92% |

| Modulus of elasticity | 76KNmm – 2 |

| Tensile strength | 40- 120Nmm – 2 |

| Glass stress optical constants | 3.8 * 10-6 |

| Processing temperature (104dpas) | 1220 ℃ |

| Coefficient of linear expansion (20-300 ℃) | 3.3 * 10-6 K – 1 |

| Density (20 ℃) | 2.23gcm – 1 |

| Specific heat | 0.9jg – 1K- 1 |

| Thermal conductivity | 1.2Wm – 1K- 1 |

| Water resistance (International Organization for standardization 719) | 1 level |

| Acid resistance (International Organization for standardization 195) | 1level |

| Alkali resistance (International Organization for standardization 695) | 2level |

High Borosilicate Glass